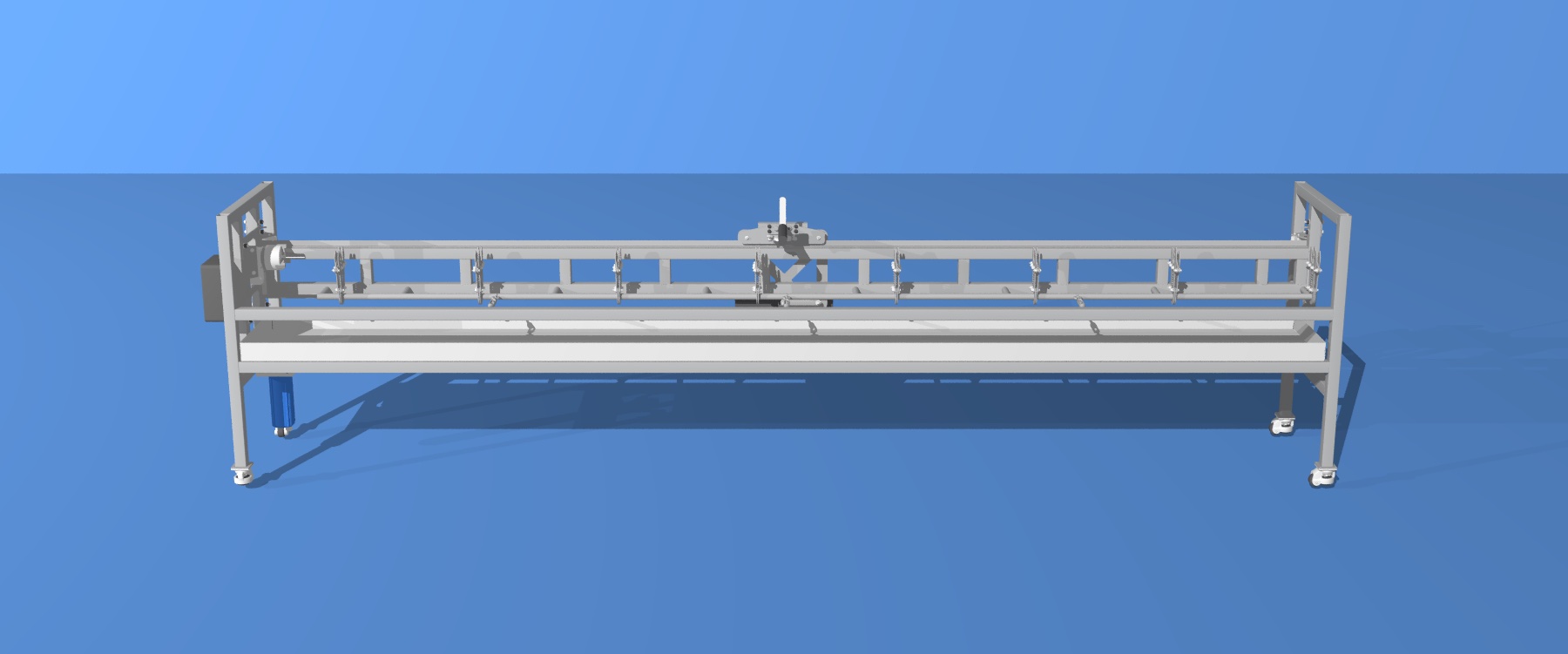

The Arma CNC Tube notcher automates cutting of metal tubing and pipe with coping for joints, tabs and slots for alignment and is compatible with the Arma Tube Bender complex bent tubing fabrication projects designed from CAD models.

The CNC Tube Notcher kit contains hardware components, electronics and software to be used with a customer fabricated steel rail and frame made along with a customer supplied computer, plasma torch, air compressor and water trough.

The Arma Tube Notcher is ideal for fabricators building round tube structures such as vehicle chassis, roll cages, bumper cages, truck racks, etc.

The tube notcher supports the cutting of Steel and Aluminum round tubing and pipe with an outer diameter between 1” and 2”.

Wall thickness up to 3/8th inch is supported. Square tubing is not supported by this product.

Two axis positioning and cutting is supported. The torch cutter is always positioned perpendicular to the tube surface as the tube rotates and the torch travels along the length. This means that there may be a wedge shape that needs to be welded on coped joints especially for tubing with a thick wall.

The maximum supported length of tube and pipe is flexible as the length of the frame and rail can be customized during assembly. The reference notcher is 14’ wide supporting tubing with a maximum length of 12’. The notcher can be made smaller to accommodate confined workspaces and lengthened to cut full length tubes 24’ long.

Control software in the Arma Design Studio application supports fabrication with new model designs or existing third parts cad models imported. Optionally a Mach3 compatible controller solution can be provided for customers wishing to use Mach3.

The Arma CNC Tube Notcher is intended to be an affordable automation tool for individual builders, medium sized business and industrial manufacturers.

Complex tube structures can be modelled in CAD software and fabricated in an efficient, accurate and repeatable manner.

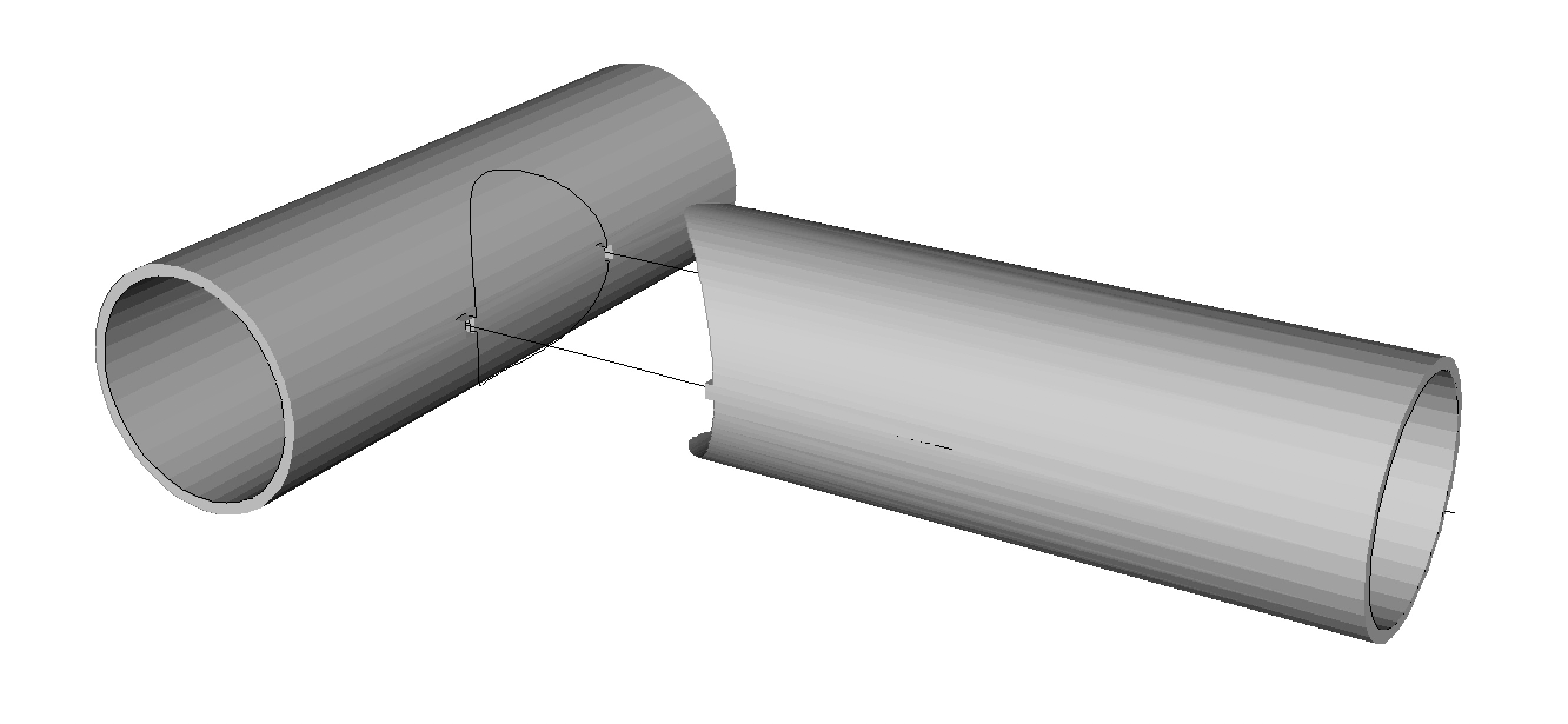

Tube structures can be cut with coping edges for accurate fitment to connecting tube where it can be welded in place.

The Arma Design Studio CAD/CAM software can generate notch profiles for intersecting tubes with tabs in one part and corresponding slots in the connecting part. This aids in verifying alignment as tubes can only fit together in the correct location as well aiding in assembly where the tabs hold parts in place more easily resulting in less jig scaffolding for complex projects.

|